Modular House 1.2

BUILT-UP AREA – 16.8m²

DIMENSIONS – 7.00m x 2.4m x 2.70m

PRICE

14.200 GBP

DELIVERY

30 DAYS

TECHNICAL DETAILS

BUILT-UP AREA – 16.8m²

DIMENSIONS – 7.00m x 2.4m x 2.70m

** includes transport and installation

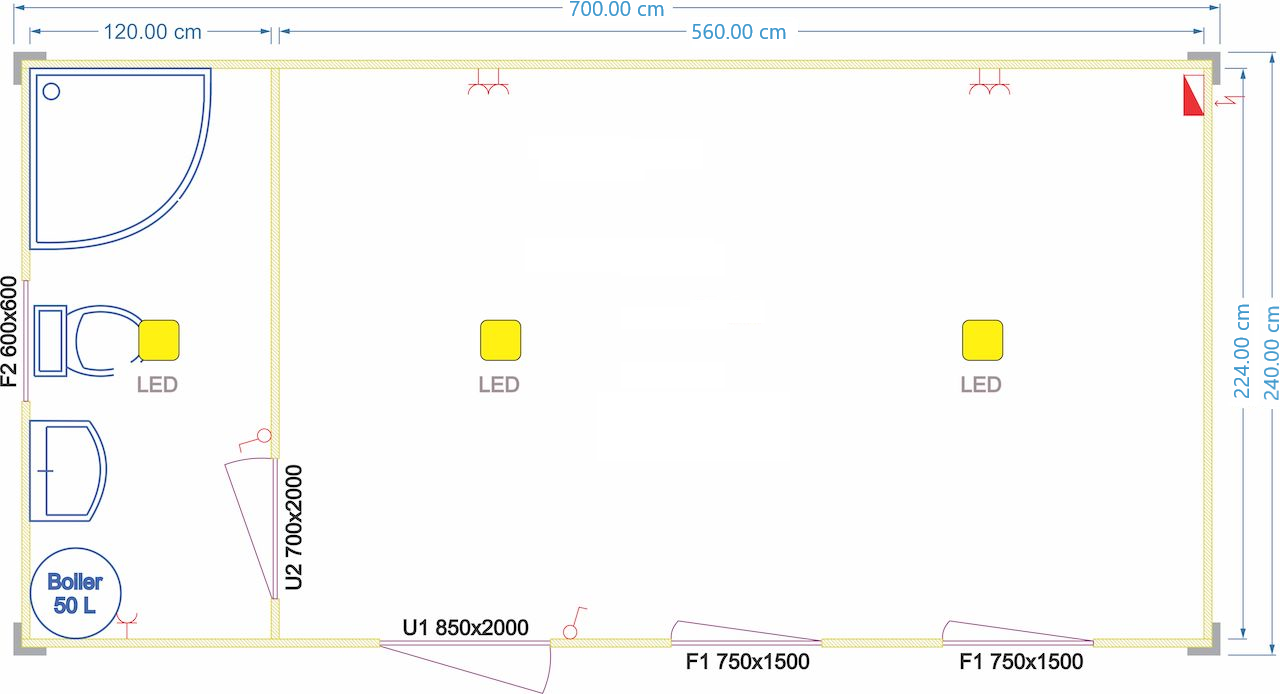

Dimensions (L x W x H): 7.00m x 2.4m x 2.70m

Frame: Single-piece – made of 2 mm galvanized sheet, cold-rolled, exclusive for container construction, primed and electrostatically painted for increased corrosion resistance.

Floor: 0.3 mm corrugated galvanized sheet, wood beams (100 x 100 mm), 100 mm mineral wool, 18 mm raw chipboard, parquet foil and 6 mm laminate flooring, in the toilet area the laminate flooring is replaced with heavy-duty PVC carpet.

Ceiling: 0.5 mm smooth galvanized sheet, wood beams, 100 mm mineral wool, and 16 mm white melamine chipboard.

External and internal walls: sandwich panels with 40 mm polyurethane foam

Access door: PVC windows 850 x 2000 mm – 1 piece – with Float glass + Lowe and panel**

Internal door: PVC windows 700 x 2000 mm – 1 piece – with panel

Windows: PVC windows 750 x 1500 mm, one swing-out leaf – 2 pieces

PVC windows 600 x 600 mm, one swing-out leaf – 1 piece

Electrical installation: differential of 0.03 A

Automatic fuse 25 A (sockets)

Automatic fuse 6 A (lighting)

Cabling: MYF 2.5 sockets MYF 1 lighting

Power supply plug: 32 A

Power supply socket: 32 A

Schuko socket 16 A double - 2 pieces

Schuko socket 16 A single - 1 piece

LED – 3 pieces.

1 toilet bowl;

1 washbasin;

1 washbasin furniture;v 1 mirror;

1 shower cabin;

1 electric boiler 50 L

– – Walls: The walls are made of insulated concrete blocks with a thickness of 24 cm and 10 cm of polystyrene insulation. This is equivalent to the insulation of a conventional concrete block wall with a thickness of 34 cm.

- Ceiling: The ceiling is made of insulated concrete blocks with a thickness of 24 cm and 10 cm of polystyrene insulation. This is superior to the insulation of a conventional wooden floor with a thickness of 10 cm of mineral wool.

- Floor: The floor is made of insulated concrete blocks with a thickness of 24 cm. This is equivalent to the insulation of a conventional concrete floor.

- Windows: The windows have a U-value of up to 1.0 W/m²K, which meets current and future thermal insulation requirements. This allows for a window U-value of up to 0.67 W/m²K. The system is constantly being developed to meet future energy efficiency standards and requirement

s.

1. Project planning: The customer works with Home Intelligent to create a custom project that meets their needs and budget. This includes the layout of the interior and exterior, as well as the type of finishes.

2. Budget and contract: Home Intelligent provides the customer with a detailed budget for the project and a contract that outlines the scope of work and the terms of the agreement.

3.Production: The modular home is built in a factory according to the approved project plan.

4. Foundation and connections: The foundation is prepared and the necessary connections are made to the utilities.

5.Delivery: The modular home is delivered to the customer's site and installed.

WORK WITH US!

Take advantage of our experience.